In today’s rapidly evolving industrial landscape, the integration of artificial intelligence into manufacturing processes has transformed traditional operations in significant ways, particularly in brush machine factories, highlighting the importance of Meixin Brush Machine Maintenance to ensure optimal performance and longevity of equipment.

In today’s rapidly evolving industrial landscape, the integration of artificial intelligence into manufacturing processes has transformed traditional operations in significant ways, particularly in brush machine factories, highlighting the importance of Meixin Brush Machine Maintenance to ensure optimal performance and longevity of equipment.

In today’s rapidly evolving industrial landscape, the integration of artificial intelligence into manufacturing processes has transformed traditional operations in significant ways. One area where this change is particularly notable is in brush machine factories, where efficiency and precision are paramount. As companies seek to optimize production lines and enhance quality control, AI technology emerges as a vital tool that can streamline operations and improve outcomes.

A prime example of innovation in this sector is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of expertise and a focus on producing advanced 2-5 axis machines, the company stands out as a leader in the field. By embracing AI, they can not only enhance their manufacturing capabilities but also ensure that they remain competitive in a global market where speed and accuracy are essential. The synergy between AI and traditional manufacturing practices heralds a new era for brush machine factories, promising improved productivity and greater adaptability to changing customer demands.

Overview of Jiangmen Meixin Comb Brush Making Machine

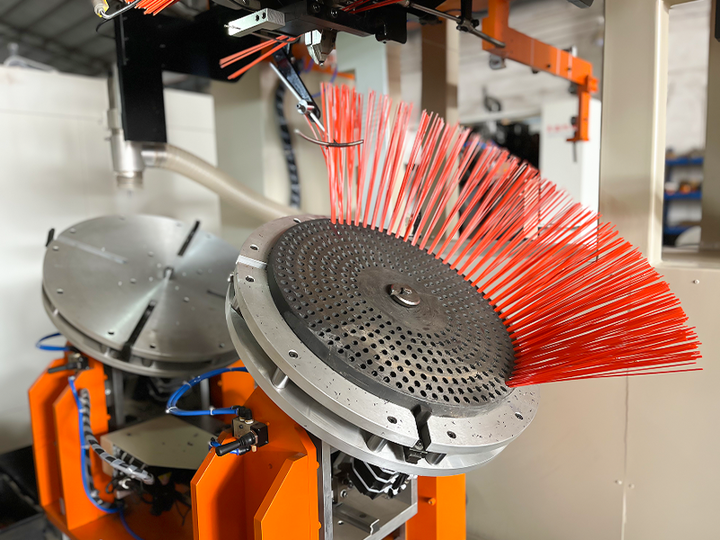

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a leading entity in the brush machine industry, with a rich history of 37 years dedicated to the design and production of advanced machinery. This expertise is reflected in their special focus on 2-5 axis machines, which are pivotal in modern brush manufacturing applications. The company’s longevity and commitment to innovation have positioned it as a trusted name among manufacturers worldwide.

The company’s state-of-the-art production facilities employ cutting-edge technologies, ensuring high-quality output that meets the diverse needs of the brush industry. With a strong emphasis on research and development, Jiangmen Meixin integrates the latest advancements in automation and precision engineering into their machines. This allows customers to benefit from increased efficiency and reliability in their production processes.

Jiangmen Meixin’s reputation is built not only on their quality machines but also on their commitment to customer satisfaction. The company offers comprehensive support and consultation services, ensuring that clients can maximize the capabilities of their equipment. This customer-focused approach, combined with decades of technical accumulation, has solidified Jiangmen Meixin’s position as a pivotal player in the global brush machine market.

Technological Advancements in Brush Machine Manufacturing

The rise of Artificial Intelligence has significantly transformed the landscape of brush machine manufacturing, particularly for companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of expertise, the integration of AI technologies has enhanced production efficiency and precision. These advancements enable machines to perform complex tasks with high accuracy and speed, leading to reduced production times and minimized waste.

Automation powered by AI allows manufacturers to streamline operations, optimizing workflows and utilizing resources effectively. AI-driven predictive maintenance ensures that machines operate at peak performance, reducing downtime and operational costs. This technology can analyze machine data in real-time, identifying potential issues before they lead to breakdowns, which is crucial in maintaining the quality and consistency of brush products.

Moreover, the incorporation of AI in design and manufacturing processes fosters innovation. By leveraging data analytics, Jiangmen Meixin can quickly respond to market demands and customize products to meet specific customer needs. This adaptability not only enhances competitiveness but also positions the company as a leader in the brush machine industry, continually pushing the boundaries of what is possible in production technology.

The Impact of AI on Production Efficiency

The integration of AI technologies in brush machine factories has significantly enhanced production efficiency. With companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. utilizing advanced AI systems, the precision and speed of machine operations have improved remarkably. By automating repetitive tasks and optimizing production workflows, factories can operate at higher output levels while reducing human error.

AI-driven systems also facilitate predictive maintenance, allowing factories to anticipate equipment failures before they occur. This proactive approach minimizes downtime and ensures that the manufacturing process remains uninterrupted. As a result, brush machine factories can maintain a steady production flow, leading to better resource allocation and improved overall productivity.

Furthermore, AI enables a level of customization that was previously unattainable. Through machine learning algorithms, factories can analyze customer demand trends and adapt production schedules accordingly. This adaptability not only meets market needs but also contributes to reduced waste and improved profitability, showcasing how AI plays a pivotal role in revolutionizing the manufacturing landscape.

Case Studies of AI Implementation

One notable example of AI implementation in brush machine factories is seen in Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. This leading company has integrated AI technologies into their production processes to optimize efficiency and reduce waste. By utilizing machine learning algorithms, they analyze production data to predict maintenance needs and prevent unexpected machine failures, thus minimizing downtime and enhancing productivity.

Another impressive application of AI in this industry is in the design phase of brush manufacturing. Jiangmen Meixin has adopted AI-driven design tools that automate the creation of 2-5 axis machine configurations. These tools allow engineers to experiment with various parameters and instantly visualize the impact on performance, significantly speeding up the innovation cycle while maintaining high standards of quality and precision in the final products.

Additionally, AI is revolutionizing quality control in brush machine factories. With advanced computer vision systems, Jiangmen Meixin can monitor the output in real time, identifying defects or inconsistencies as products are manufactured. This immediate feedback loop not only ensures superior product quality but also provides valuable data that can be used for continuous improvement in manufacturing processes, further solidifying the company’s reputation in the industry.

Future Trends in AI and Brush Machine Factories

As brush machine factories continue to evolve, the integration of artificial intelligence is set to redefine operational efficiencies and product quality. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., with their extensive experience in producing 2-5 axis machines, are already exploring advanced AI algorithms that can optimize production processes. This includes predictive maintenance, where AI systems can analyze machine data to forecast potential failures before they occur, significantly reducing downtime and maintenance costs.

Additionally, AI-driven data analytics will enhance decision-making processes within brush machine factories. By leveraging real-time data from production lines, factory managers can identify bottlenecks and inefficiencies swiftly. This capability not only allows for quicker adjustments to production but also enhances overall quality control, ensuring that every brush produced meets high standards. The application of AI in quality assurance processes through machine learning techniques will enable continuous improvement in manufacturing outcomes.

Looking ahead, the future will likely see a rise in collaborative robots, or cobots, powered by AI in brush machine factories. These robots will work alongside human operators, handling repetitive tasks while allowing skilled workers to focus on more complex aspects of production. As factories like Jiangmen Meixin further embrace automation and smart technologies, the synergy between AI and human expertise will drive innovation, leading to more sustainable and efficient manufacturing practices in the brush industry.